Industrial pest control services: Top 5 Expert Solutions

Why Industrial Facilities Can’t Afford to Ignore Pest Control

Industrial pest control services are specialized programs designed to manage pests in large-scale facilities like manufacturing plants, warehouses, and distribution hubs. Unlike residential services, these solutions address the unique challenges of vast spaces, complex operations, and strict regulatory requirements to protect inventory, maintain compliance, and safeguard your brand.

Here’s what you need to know about industrial pest control:

- What it includes: Comprehensive inspections, customized treatment plans, ongoing monitoring, detailed documentation, and compliance support.

- Who needs it: Food and beverage processing, pharmaceutical manufacturing, warehousing, healthcare, and hospitality businesses.

- Why it matters: A single pest can trigger production shutdowns, product recalls, regulatory fines, and severe brand damage.

- Key approach: Integrated Pest Management (IPM) focuses on prevention through sanitation, exclusion, and targeted treatments.

- Cost factors: Facility size, pest type, infestation severity, and service frequency (internet data suggests annual contracts can range from $5,000 to over $50,000, not actual Waltham Pest Control costs).

In an industrial facility, a single mouse or cockroach can cascade into six-figure losses. Pests spread disease, trigger health code violations, and can even force closures. The stakes are too high to treat pest management as an afterthought. Your facility is under constant threat from pests like rodents, cockroaches, flies, and birds that can damage structures, contaminate products, and spread pathogens.

Each facility has unique vulnerabilities, from the zero-tolerance standards of food processing plants to the endless hiding spots in warehouses. The old approach of calling an exterminator only when you see a problem is dangerously outdated. Modern industrial pest management is proactive, documented, and data-driven, preventing infestations before they start and protecting your operational integrity.

I’m Waltham Pest Control, President & CEO of Waltham Pest Control. For over 40 years, we’ve provided comprehensive industrial pest control services to facilities across Eastern Massachusetts, changing pest management from a reactive expense into a proactive investment.

Important industrial pest control services terms:

The High Stakes: Why Industrial Pest Control is Non-Negotiable

Industrial pest control isn’t optional—it’s an existential threat to your operation. In a home, a mouse is an annoyance. In your facility, that same mouse can contaminate a production run, trigger a regulatory inspection, and cost you hundreds of thousands of dollars. The scale changes everything.

Industrial environments are a battleground. Vast spaces, complex layouts, constant traffic through loading docks, and 24/7 operations create prime real estate for pests. Unlike a home with defined boundaries, your facility has countless entry points and offers continuous warmth, shelter, and food sources. This complexity demands a professional approach.

Pests cause physical destruction by chewing through wiring, drywall, and stock, but the health risks are even greater. They can spread diseases like Salmonella and Hantavirus, sickening employees and customers. An infestation can erode customer trust, lower employee morale, and damage your reputation for years. In regulated industries like food processing or pharmaceuticals, a single pest can shut you down. Investing in professional industrial pest control services safeguards your assets, ensures a healthy work environment, and protects your brand.

Be aware of these common industrial pests:

- Rodents: Mice and rats gnaw on wiring and structures, contaminate food, and spread disease.

- Cockroaches: Resilient and fast-breeding, they contaminate surfaces and spread bacteria that cause food poisoning.

- Stored Product Pests: Beetles and moths infest raw materials and finished goods, leading to spoilage and recalls.

- Flies: These disease vectors carry pathogens like Salmonella and E. coli, posing a critical threat.

- Birds: Their corrosive droppings damage buildings and products, and they can clog ventilation systems.

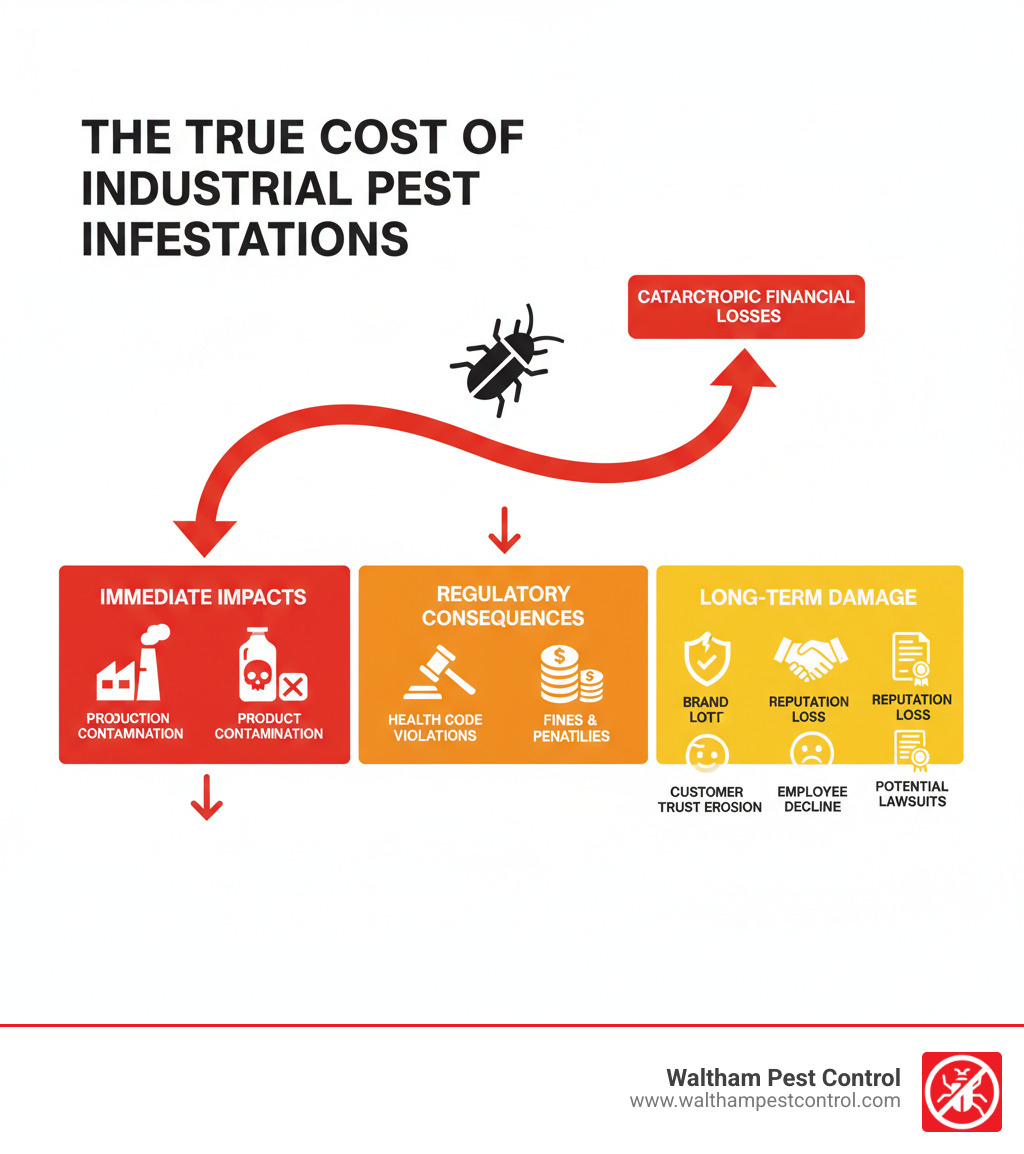

The Cost of an Infestation: Damage, Dollars, and Downtime

The financial and operational fallout from a pest infestation is staggering. It’s a domino effect that impacts your entire business.

- Product Contamination and Loss: Pests directly spoil products, leading to costly recalls and financial losses. One contaminated batch can affect thousands of units.

- Structural and Equipment Damage: Rodents chew through wiring, causing equipment failures, power outages, and fire hazards. Repair costs and production downtime compound quickly.

- Regulatory Fines and Penalties: Facilities in food, pharmaceutical, and healthcare sectors face strict regulations. Infestations lead to significant fines and shutdowns for health code violations.

- Business Closure and Legal Action: Severe infestations can force temporary or permanent closures. Lawsuits from customers or employees over health and safety also become a real risk.

- Reputational Damage: A single pest sighting shared online can tarnish your brand, erode customer trust, and impact future business for years.

- Employee Morale and Health Risks: Unsanitary conditions hurt morale and productivity, creating a toxic work environment and increasing employee turnover.

Industries Most at Risk

While any facility is vulnerable, certain industries require highly specialized industrial pest control services due to acute risks.

- Food and Beverage Processing: These are prime targets with abundant food sources and strict hygiene standards, where contamination can halt production instantly.

- Pharmaceutical Manufacturing: Pests can contaminate sterile products and compromise research, threatening regulatory compliance and public health.

- Warehousing and Logistics: Vast spaces with stored goods offer ample harborage for pests that damage inventory throughout the supply chain.

- Healthcare Facilities: Pests pose severe health risks to vulnerable patients and can compromise the sterile environments required in hospitals and clinics.

- Hospitality: Hotels and resorts live and die by their reputation. Pests like bed bugs and cockroaches can cause irreparable brand damage and lead to lawsuits.

For more detailed information on how we tailor our solutions for various businesses, please explore our commercial pest control services.

The IPM Blueprint: A Modern Approach to Industrial Pest Management

Effective industrial pest control services aren’t about reacting with a spray can. The modern, sophisticated approach is Integrated Pest Management (IPM). Championed by the Environmental Protection Agency (EPA), IPM is a proactive strategy that uses a combination of methods to manage pests while minimizing risks to people, products, and the environment.

IPM is built on knowledge, not just chemicals. We focus on understanding pest biology and eliminating the conditions that attract them. This blueprint involves meticulous documentation, stringent safety protocols, and continuous adaptation to your facility’s needs, addressing issues before they escalate into costly infestations.

Step 1: Comprehensive Site Inspection and Assessment

Everything starts with a thorough inspection of your facility. Our certified technicians don’t use a one-size-fits-all approach. We investigate your operation to identify which pest species are present or likely to invade. We locate all potential entry points, from cracks in the foundation to gaps around utility lines and loading dock doors.

We then assess risk factors by evaluating high-potential areas like food storage, waste disposal, and utility rooms. This detailed assessment allows us to understand your facility’s unique ecosystem and develop a precise, effective strategy. For more on this crucial first step, visit our pest inspection services page.

Step 2: Customized Strategy and Treatment

With a complete picture of your vulnerabilities, we develop a unique treatment plan. This is where the “integrated” part of IPM shines.

- Prevention: We start with sanitation recommendations to eliminate pest attractants like food and water sources.

- Exclusion: We implement physical barriers to keep pests out, such as sealing cracks, repairing screens, and installing door sweeps.

- Targeted Treatments: When necessary, we use treatments strategically. This includes placing baiting systems, using traps in high-activity areas, and applying eco-friendly products with minimal risk and maximum effectiveness.

Safety is non-negotiable. Our technicians use only approved products and follow strict protocols to ensure treatments are conducted safely with minimal disruption. We are committed to environmentally responsible solutions. Learn more about our IPM Program.

Step 3: Ongoing Monitoring and Prevention

Pest control is not a one-time event. Ongoing monitoring is the most critical part of our IPM blueprint, as conditions in your facility are always changing. We schedule regular visits to stay ahead of potential problems, checking for new pest activity and evaluating the effectiveness of our treatments.

Our team uses advanced tools, including barcode scanning technology, to track pest activity and treatment data. This allows us to identify trends and fine-tune our strategy in real-time. This systematic approach ensures your facility remains pest-free and compliant with regulatory requirements, preventing future infestations rather than just reacting to them. Find out more about our long-term solutions through our green pest control options.

Why Choose Waltham Pest Control: The Hallmarks of a True Industrial Partner

Choosing a pest control partner for an industrial facility is a high-stakes decision. You need a provider who understands the complexities of your environment, where a single pest can trigger shutdowns and recalls. At Waltham Pest Control, we deliver the proactive protection, regulatory expertise, and the detailed documentation modern operations demand. The difference between our professional management and a DIY approach is stark.

| Feature | Professional Industrial Pest Control | Unmanaged/No Pest Control (or DIY) |

|---|---|---|

| Expertise | Certified, experienced technicians with industrial-specific training | Limited knowledge, often misidentifies pests, ineffective treatments |

| Compliance | Ensures adherence to regulations (FDA, USDA, AIB, health codes) | High risk of non-compliance, fines, and legal action |

| Long-Term Cost | Prevents costly damage, recalls, and operational shutdowns | High costs from damage, product loss, and potential closures |

| Safety | Prioritizes employee and product safety with targeted, eco-friendly IPM | Risk of improper chemical use, health hazards, and contamination |

| Guarantees | Offers satisfaction and re-treatment guarantees | No guarantees, problems often recur |

| Documentation | Provides detailed reports for audits and trend analysis | No records, difficulty proving compliance |

Our Essential Qualifications and Certifications

As your industrial pest control partner, Waltham Pest Control meets and exceeds the highest industry standards. These are the non-negotiable qualifications we bring to every facility:

- Licensed and Insured: Our technicians are all state-licensed, and our company carries comprehensive insurance for your complete protection.

- Professional Certifications: We hold QualityPro certification from the National Pest Management Association (NPMA), which signifies our commitment to professionalism, background checks, and ongoing training.

- Industry-Specific Training: Our team understands the specific protocols of regulated industries, including HACCP and third-party audit requirements (e.g., AIB International).

- Experience with Audits: With over 40 years of experience, we are true partners in helping you prepare for inspections, maintain proper documentation, and successfully pass audits.

Understanding the Cost of Professional Industrial Pest Control Services

Professional industrial pest control services are an investment, not an expense—they are insurance against catastrophic losses. Costs vary based on facility size, operational complexity, pest type and severity, and service frequency. For example, a food processing plant may need monthly service, while a low-risk warehouse might only need quarterly visits.

Based on internet data, yearly industrial pest control contracts can range from $5,000 to over $50,000. This wide range reflects the diversity of industrial facilities. The cost of not having professional pest control—from recalls, fines, and downtime—can easily dwarf this investment.

Preparing Your Facility for Industrial Pest Control Services

A successful pest management program is a partnership. You can support our efforts with these key steps:

- Improve Sanitation: Regular cleaning removes food debris and water sources that attract pests. Ensure waste receptacles have tight-fitting lids.

- Reduce Clutter: Organized storage areas eliminate hiding spots for pests and allow for more thorough inspections.

- Seal Entry Points: Block pests by sealing cracks in foundations, gaps around utility lines, and damaged door sweeps. A mouse can fit through a dime-sized hole.

- Communicate with Staff: Train employees to recognize and report signs of pest activity. They are your first line of defense.

- Provide Access: Ensure our technicians have unobstructed access to key areas like storage rooms, utility closets, and loading docks during service visits.

Frequently Asked Questions about Industrial Pest Control

We know you have questions about protecting your facility. Here are straight answers to the most common concerns we’ve heard over 40 years of providing industrial pest control services to Eastern Massachusetts businesses.

How often is industrial pest control needed?

Service frequency depends entirely on your specific situation: your industry, your facility’s risk level, and regulatory requirements. A food processing facility may require monthly service to comply with strict hygiene standards, while a warehouse storing non-food items might only need quarterly visits.

After a comprehensive inspection, we recommend a custom plan with the optimal service frequency for your operations. However, year-round pest control is essential for all industrial facilities, as pests constantly seek indoor shelter, especially as seasons change.

Are pest control treatments safe for my employees and products?

Yes, absolutely. The safety of your employees and products is our highest priority. We strictly adhere to Integrated Pest Management (IPM) principles, which prioritize low-impact solutions. This means we use targeted applications, baiting systems, mechanical traps, and physical exclusion methods before considering conventional pesticides.

When chemical treatments are necessary, we use only products approved for industrial settings, applied by licensed professionals following rigorous safety protocols. We schedule treatments to minimize disruption and ensure a safe, healthy environment.

What are the most common signs of a pest infestation in a large facility?

In a large facility, pests can hide easily, but they always leave clues. Training your staff to spot these signs is a critical part of an effective pest management program.

- Physical Evidence: Look for rodent droppings, gnaw marks on structures or packaging, and damaged goods.

- Unusual Sounds: Listen for scratching or scurrying noises within walls, ceilings, or behind equipment.

- Odors: A persistent musty or unpleasant smell can indicate a significant rodent or cockroach presence.

- Nests or Harborage: Be aware of shredded paper, fabric, or mud tubes along walls, which indicate nesting sites.

- Live Pests: Seeing a single pest during the day often indicates a much larger, hidden population.

If you notice any of these signs, don’t wait. Early detection is key to preventing a small problem from becoming a costly infestation.

Secure Your Operations with Expert Pest Management

Your industrial facility is a significant investment, and pests threaten it every day. A robust pest management strategy isn’t just for compliance—it’s about protecting your bottom line, ensuring a safe workplace, and running your operations smoothly and profitably.

Partnering with a professional for industrial pest control services helps you pass audits with confidence, avoid crippling fines, and maintain a workplace free from health concerns. It transforms pest management from a reactive headache into a proactive strength.

At Waltham Pest Control, we’ve spent over 40 years earning the trust of businesses throughout Eastern Massachusetts. From Acton to Andover, Arlington to Bedford, Boston to Burlington, Cambridge to Concord, and across Framingham, Lexington, Lowell, Newton, Peabody, Quincy, Salem, Waltham, Weymouth, and dozens of other communities in Middlesex, Essex, and Norfolk Counties, we’ve protected industrial facilities just like yours. Our team of licensed, insured, and highly trained professionals brings unparalleled quality and commitment to every site.

We understand the stakes. We’ve helped food processors maintain zero-tolerance standards, supported warehouses in protecting millions in inventory, and assisted manufacturers in preventing costly equipment failures.

Your facility deserves protection from experts who truly understand industrial pest challenges. Don’t wait for a pest sighting to trigger a crisis. Let us help you build a proactive defense that keeps your operations secure, your employees safe, and your reputation intact.

Contact us today for a comprehensive assessment of your industrial facility. We’re ready to put our four decades of experience to work protecting your business.